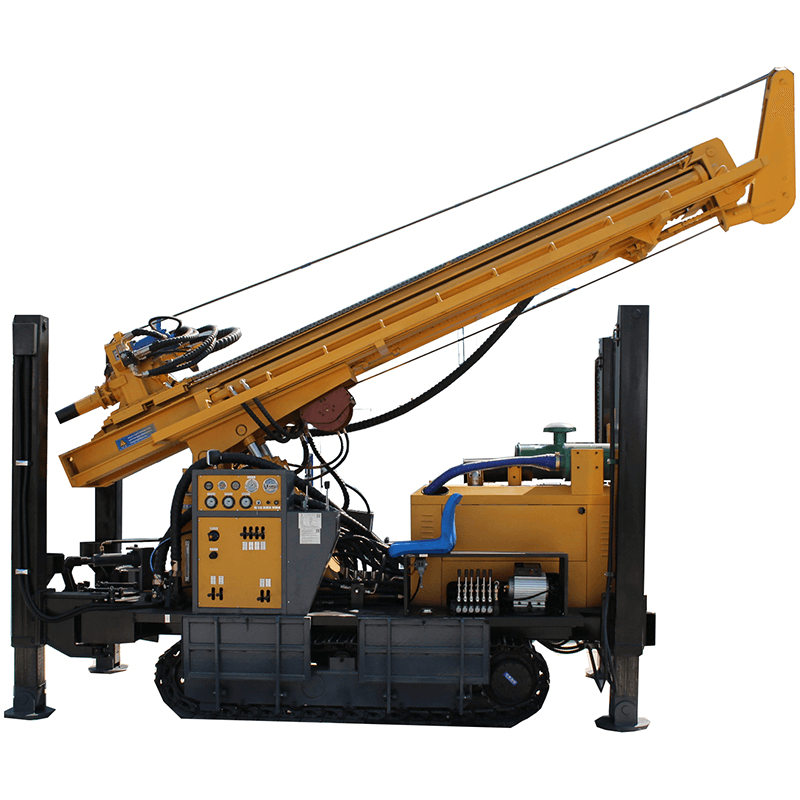

A pneumatic well drilling rig is a light, efficient, multi-functional drilling equipment. It is mainly used for industrial and civil well drilling and geothermal drilling. It has the advantages of a compact structure, and flexible movement. Good for water well drilling in mountainous areas and rock formations.

The water well drilling rig can carry out different drilling works within the drilling diameter range of 245-294mm. The water well rig uses new hydraulic technology to support high torque hydraulic motors to rotate. The well-known multi-cylinder engine powers the hydraulic system. The two-stage compressed air filter and special design for screw air compressors extend the life of the diesel engine. The pump set reduces maintenance costs. The centralized control of the hydraulic console is easy to operate.

When the drill pipe needs to be increased after the depth of 1 drill pipe, stop pushing downward in advance, then stop the rotation, and then turn off the cooling water;

Use the handle to grasp the drill pipe and then open the tuning flow valve;

Then it is reversed, and the pushing cylinder is retracted at the same time, taking the water pipe away from the drill pipe;

Stop rotation and change the fast-forward and the fast backward handles position, the holding plate will quickly return to its original position;

Connect the drill pipe to the first drill pipe and the rotor rotates and moves forward. When the cone thread of the drill pipe contacts the taper thread of the drill pipe, releases the jaw plate, and the drill pipe connection is completed.